The Delair UX11 is a lightweight, professional grade fixed wing designed to cover more ground – and recent sales for mining and quarry environments indicate that customers are adopting it as a tool of choice.

The Delair UX11 is a lightweight, professional grade fixed wing designed to cover more ground – and recent sales for mining and quarry environments indicate that customers are adopting it as a tool of choice.

The recently released FAA Aerospace Forecast said that consumer grade drones used for commercial purposes (average price $2,500) currently represent 95% of the market compared with professional grade drones (defined by the FAA as having an average price of $25,000 – although the UX11 retails for significantly less than that) . That’s changing rapidly, however, as larger industrial applications expand and the ROI for uses in the mining and power sectors becomes more clear.

In the mining industry, drones are now becoming a valuable resource for managing resources and planning excavation. Drones provide an inexpensive means of precise data collection that can significantly impact a company’s bottom line.

The following is a Delair press release.

WOOD ADOPTS DELAIR UX11 UAV FOR LARGE SCALE SURVEYING AND QUANTITY MEASUREMENT FOR MINES, QUARRIES

Global engineering services leader implements fixed-wing aerial data collection program with support from Delair partner Frontier Precision

LOS ANGELES– May 7, 2019–Delair,a leading supplier of commercial drone solutions, along with one of its regional resellers, Frontier Precision, today announced that Wood has adopted the Delair UX11 high-performance UAV for its work in site planning and asset management in mining and quarry projects in the western US. Wood – a global leader in the delivery of project, engineering and technical services to the energy, industry and built environment sectors -is initially deploying the drone to do high accuracy, 3D topographic surveys and materials quantification for mineral mining in Idaho and Wyoming. It is the first fixed-wing UAV Wood has deployed in the Western US.

“For the scale of the projects we are performing, and the accuracy required, adopting the Delair UX11 was a logical choice. Its long-range capabilities allow us to cover areas not feasible with other data collection methods like hover craft drones or by foot, so it reduces the cost and time involved. It integrates well with our existing work flows, and features such as the PPK function deliver additional benefits in terms of the precision and flexibility required in challenging environments,” said Greg Meinecke, Technical Services Manager at Wood. “We have received excellent support from Frontier Precision and Delair in helping us deploy our first fixed-wing UAV missions and are already seeing results.”

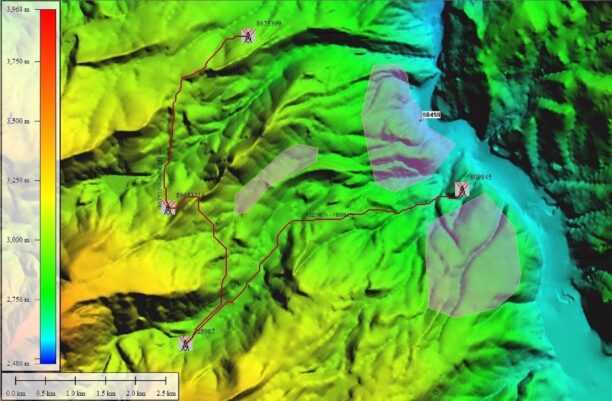

Wood is deploying the drone in remote areas where its heavy civils team is performing extensive excavation and site preparation for phosphate mining activities, a project covering more than 200 acres. Of critical importance for operations is an ability to precisely quantify the volume of materials being removed to ensure a high degree of accuracy in planning and invoicing.

Wood turned to the Delair fixed-wing UAV to deal with the scale of the terrain that needed to be surveyed, as well as the challenge of taking measurements in an active mine site area, including the safety hazards of having personnel on the ground in rough terrain and around large, moving equipment. Flying at 400 feet above the project areas and often at times using beyond visual line of sight (BVLOS) flight plans, Wood technicians were able to use the precision data collection features of the Delair UX11 to acquire large amounts of highly accurate imagery that could be processed to generate detailed topographical reports.

“We are able to get surveys covering large tracts of land done in a very short amount of time, so it ends up being much more cost effective for us and the client. More importantly, we can provide the mine owners a great deal of confidence in the accuracy of the work being performed and the quantities of resources involved. In the end, everyone agreed on the material quantities as the technology is very reliable,” Meinecke noted.

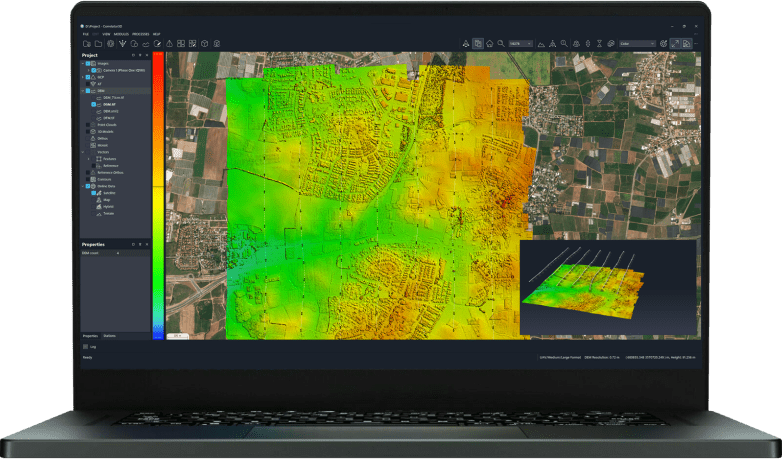

Frontier Precision worked alongside Wood’s engineering and field experts to evaluate the Delair drone, and ensure it met the firm’s requirements, including integration with other important tools the firm uses such as AutoCad, Trimble Business Center, and the Pix4D photogrammetry suite.

Wood’s team noted the ease of use of the Delair UAV, especially given this was their first experience with fixed-wing flying. The firm was able to train several pilots who specialize in different types of projects, and expects to deploy the drone on other infrastructure, mining and construction projects around the US. The team also noted the Delair UX11’s embedded global shutter camera as well as its PDK (post processed kinematic) capabilities as key to ensuring greater precision in its data collection. With PPK, GPS data from both on-board and off-board systems can be matched after the mission, providing higher degrees of accuracy of the images collected.

The Delair UX11 UAV, introduced commercially last year, is one of Delair’s top-of-the-line drones. The fixed-wing drone is an innovative hardware-software platform that provides highly accurate images for survey-grade mapping, with on-board processing capabilities and real-time, long-range control via 3G/4G cellular networks or radio links. The platform’s enhanced centimeter-level precision along with its efficient operational characteristics make it the most cost-effective solution for large area surveying and mapping.

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, a professional drone services marketplace, and a fascinated observer of the emerging drone industry and the regulatory environment for drones. Miriam has penned over 3,000 articles focused on the commercial drone space and is an international speaker and recognized figure in the industry. Miriam has a degree from the University of Chicago and over 20 years of experience in high tech sales and marketing for new technologies.

For drone industry consulting or writing, Email Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife here.

[…] DRONELIFE […]