Percepto, Chevron team on autonomous drone inspections

By DRONELIFE Features Editor Jim Magill

Israel-based Percepto is combining artificial intelligence (AI) and drone technologies to conduct safety inspections across Chevron’s far-flung assets in the western U.S., limiting the need for human-led inspection trips.

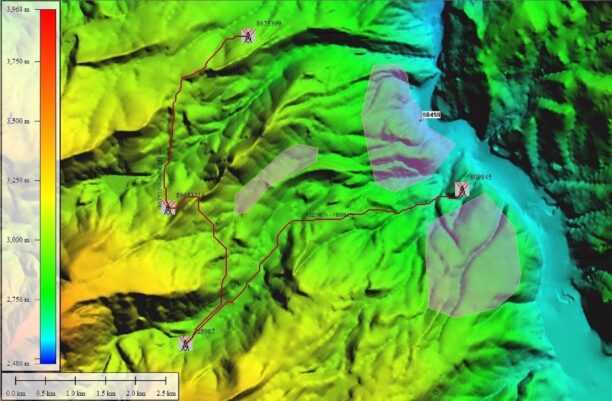

The two companies recently announced the successful completion of the first six months of a pilot program to test the technology under field conditions in two climatically distinct regions where Chevron operates, the Permian Basin of West Texas and the Rocky Mountain region of western Colorado.

“We have one of our systems deployed in our West Texas shale asset, and we have another system that we’re testing in our Colorado upstream shale,” Russell Robinson, a program manager for Chevron’s Facilities and Operations of the Future team, said in an interview.

Robinson said he is excited about the initial results of the pilot program, which enables Chevron personnel to keep an eye on multiple assets spread out over a large geographic area, from a remotely located control center. The pilot program is slated to run through the end of this year.

Ariel Avitan co-founder of Percepto, said the company’s canopy waiver from the FAA allows Percepto to conduct multiple autonomous BVLOS missions anywhere is U.S. Class G airspace, all coordinated from its head operation office in West Palm Beach Florida.

“Percepto has a drone-in-a-box, which is part of the solution. The drone is stationary in one location and basically monitors that area of assets near the box,” he said. “And then, it also does base hopping, so it moves to another base station and then monitors that location as well.”

Employing its Percepto AIM (Autonomous Inspection & Monitoring) software, the company deploys its drones to collect different types of data – such as gas-monitoring and visual images — to provide a complete inspection picture, without having to send teams of human inspectors to remote locations, frequently under difficult environmental conditions.

Under the pilot program, each quadcopter drone deployed in one of the two Chevron operating areas carries a payload that includes an optical gas imaging (OGI) camera and a standard RGB camera. The drone’s base station is equipped for automatic charging and data upload, and includes an HVAC unit and weather station. The system’s cloud-based software includes geospatial data management and several advanced analytics algorithms, as well as numerous other operational and safety features.

“The Percepto technology leverages AI in a couple of ways. First, the drone itself flies on automated missions with logic built-in from pre-programmed flights. Secondly, when the drone is on a mission, AI built into the software enables automated alerts when it detects any anomalies to normal operations,” according to a recent press release distributed by the two companies.

The AI software facilitates the analysis of the massive quantities of data collected by the drone flights. This allows Chevron to scale its use of the autonomous drones, knowing that the data collected will give the giant oil company the information it needs to take action.

“That’s really the value for us here at Chevron for both scale and speed to scale,” Robinson said. “We’re able to monitor and launch missions from their (Percepto’s) control center in Florida, but also from our control centers, whether that be in Houston, West Texas or Colorado. That’s really powerful because you really get an efficiency of scale.”

He said that Chevron has begun to do some early lookbacks at the pilot program, with the expectation that the oil and gas company would expand its use of Percepto’s monitoring technology into other regions around the country where it operates.

“The results in some of our areas is in line with expectations, and in other areas it’s been above and beyond,” Robinson said. “So, as far as the future goes, the conversation naturally already starts to turn to the speed to scale, so we’re having those conversations with Percepto as well as other partners across the technology industries.”

Drones can perform specific inspection tasks

While the system is designed to enable the drones to perform autonomous inspections on a regularly scheduled basis, operators working from remote control centers can direct the UAV to perform specific tasks, for example focusing the drone’s cameras to zoom in on a specific valve where a leak is suspected.

“We do have both proactive and reactive missions that we can perform remotely,” Avitan said. “The reactive mode allows the operator to also manually stop the drone and look for specific items.”

He said all facets of the system, including the drones and charging stations, are built to a high degree of “ruggedization” to be able to continue to operate effectively in various environments.

“It’s a Cat-5 approved system. It’s designed to live in very harsh conditions,” Avitan said. The Percepto UAVs also are equipped with parachutes and sensors that allow them to fly safely under a wide range of difficult weather situations.

“That’s key for Chevron too, and that’s why strategically we’re testing it in West Texas and in Colorado. That gives us kind of the extremes of the weather cycle,” Robinson said. “That adds to that safety element because we can eliminate operators’ drive times on roads, especially in potential weather like snow and ice.

“That’s a huge benefit to us, as we continue to improve how we operate and ensure that our operators and our technicians are as safe as possible,” Robinson said.

Want DRONELIFE news delivered to your inbox every weekday? Sign up here.

Read more:

- Percepto Secures FAA Type Certificate, Enhancing Safety and Reliability in Drone Operations

- Percepto Receives Waiver to Operate 30 Drones Autonomously: the Holy Grail of Industrial Drone Inspections

- Percepto Investment Grows with $67 Million Round

Jim Magill is a Houston-based writer with almost a quarter-century of experience covering technical and economic developments in the oil and gas industry. After retiring in December 2019 as a senior editor with S&P Global Platts, Jim began writing about emerging technologies, such as artificial intelligence, robots and drones, and the ways in which they’re contributing to our society. In addition to DroneLife, Jim is a contributor to Forbes.com and his work has appeared in the Houston Chronicle, U.S. News & World Report, and Unmanned Systems, a publication of the Association for Unmanned Vehicle Systems International.

Jim Magill is a Houston-based writer with almost a quarter-century of experience covering technical and economic developments in the oil and gas industry. After retiring in December 2019 as a senior editor with S&P Global Platts, Jim began writing about emerging technologies, such as artificial intelligence, robots and drones, and the ways in which they’re contributing to our society. In addition to DroneLife, Jim is a contributor to Forbes.com and his work has appeared in the Houston Chronicle, U.S. News & World Report, and Unmanned Systems, a publication of the Association for Unmanned Vehicle Systems International.

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, a professional drone services marketplace, and a fascinated observer of the emerging drone industry and the regulatory environment for drones. Miriam has penned over 3,000 articles focused on the commercial drone space and is an international speaker and recognized figure in the industry. Miriam has a degree from the University of Chicago and over 20 years of experience in high tech sales and marketing for new technologies.

For drone industry consulting or writing, Email Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife here.

Leave a Reply