DJI’s Phantom 4 RTK is a professional drone for precision mapping: “providing real-time, centimeter-level positioning data for improved absolute accuracy on image metadata,” says DJI. Designed to ensure flight stability and accuracy in complex mapping and inspection missions, the world’s leading drone manufacturer claims centimeter-level accuracy for the Phantom 4 RTK.

DJI’s Phantom 4 RTK is a professional drone for precision mapping: “providing real-time, centimeter-level positioning data for improved absolute accuracy on image metadata,” says DJI. Designed to ensure flight stability and accuracy in complex mapping and inspection missions, the world’s leading drone manufacturer claims centimeter-level accuracy for the Phantom 4 RTK.

Here’s how a team of high-level mapping consultants from Japan set out to validate the drone’s accuracy – and what they found.

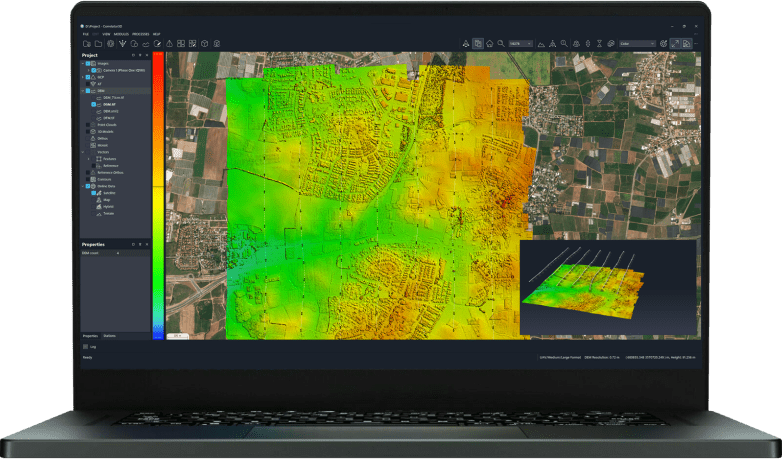

Mirukuru is a technical consultant, reseller and support provider for photogrammetry and LiDAR Mapping solutions based in Tokyo, Japan. With 20 years of experience, the Mirukuru team is committed to provide the highest product quality and support to its customers. To validate the accuracy of the DJI Phantom 4 RTK, the company used Correlator3D™, a patented end-to-end photogrammetry solution for the generation of high-quality geospatial data from satellite and aerial imagery. Originally designed for government and enterprise clients to utilize satellite data, the software now accomodates drone data.

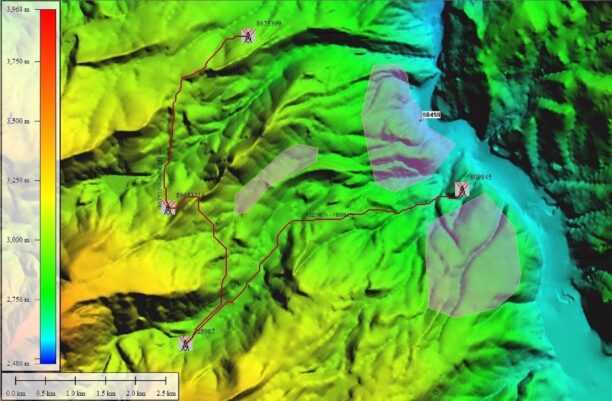

Correlator3D, produced by Canadian photogrammetry experts SimActive, performs aerial triangulation (AT) and produces dense digital surface models (DSM), digital terrain models (DTM), point clouds, orthomosaics, 3D models and vectorized 3D features. The software provides a change detection module, which allows users to compare two different digital elevation models, comparing them for any variation. Users can easily see any changes as color information – with the option of converting the mosaic to grayscale and seeing any negative elevation changes highlighted in tones of yellow to red, according to significance, and positive elevation changes shown in tones of dark to light blue.

The team performed a full-scale validation in the mountains near Hiroshima, with a unit flown by SimActive Japanese partner Mirukuru and customer Ace-1. “The area was surveyed by two independent flights at different altitude to assess consistency using Correlator3D’s change detection module”, said Mr Francois Gervaix, Technical Advisor at SimActive. “The analysis was very simple to achieve, and 3D profiles showed no bias and very limited noise.”

The team performed a full-scale validation in the mountains near Hiroshima, with a unit flown by SimActive Japanese partner Mirukuru and customer Ace-1. “The area was surveyed by two independent flights at different altitude to assess consistency using Correlator3D’s change detection module”, said Mr Francois Gervaix, Technical Advisor at SimActive. “The analysis was very simple to achieve, and 3D profiles showed no bias and very limited noise.”

“Considering that the data were acquired and processed directly in the field in a record time, the level of details that are visible and measurable in Correlator3D™ is stunning”, said Mr Shinji Inaba, Technical Manager at Mirukuru Co. Ltd., Japan. “We had independently set up five check points and the residuals are consistently in the 5cm-range, both horizontal and vertical.”

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, a professional drone services marketplace, and a fascinated observer of the emerging drone industry and the regulatory environment for drones. Miriam has penned over 3,000 articles focused on the commercial drone space and is an international speaker and recognized figure in the industry. Miriam has a degree from the University of Chicago and over 20 years of experience in high tech sales and marketing for new technologies.

For drone industry consulting or writing, Email Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife here.

[…] Source […]