Riaan Meyer is used to working on large scale renewable energy projects. “The typical solar plant in Africa is just much bigger than it is in other countries,” says Meyer. “And solar is booming on both ends – plants and residential. ” Meyer’s company GeoSUN is out in the field providing services to help renewable energy plants succeed – and drones are a proving a transformative tool for inspections in solar and wind.

Riaan Meyer is used to working on large scale renewable energy projects. “The typical solar plant in Africa is just much bigger than it is in other countries,” says Meyer. “And solar is booming on both ends – plants and residential. ” Meyer’s company GeoSUN is out in the field providing services to help renewable energy plants succeed – and drones are a proving a transformative tool for inspections in solar and wind.

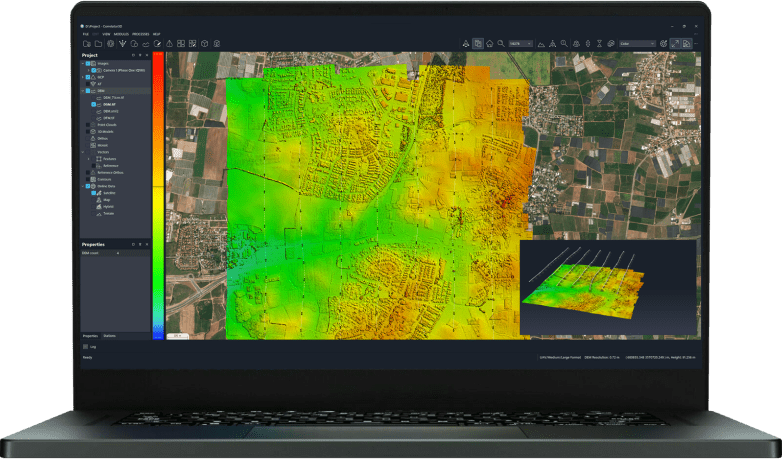

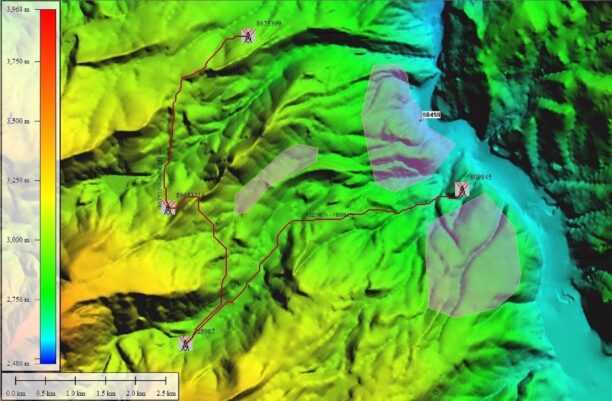

GeoSUN Africa is a spin-off of CRSSES (Centre for Renewable and Sustainable Energy Studies) at Stellenbosch University. The team provides a wide variety of testing and data collection services to help projects get off the ground and keep running, from the prospecting and evaluation phase through operation and maintenance. Drones, says Meyer, can be used at almost all renewable energy plants.

Wind turbines are 80-120 meters high (about 250 to almost 400 feet) with blade lengths of 45 meters (about 150 feet.) In Africa, wind farms have to be inspected every two years – and that’s typically done by an inspector rapelling down the structure, hopefully as the wind is not blowing. Drones can take detailed images of the structures, and inspectors can return actionable data to their clients, while staying safely on the ground.

In Solar Photovoltaic (PV) facilities, the benefits of drone technology might be even greater. Inspections can be difficult; the naked eye can’t detect damage to fragile cells in the solar panels, which could have been damaged by stress, pressure from stepping on the panels, or incorrect installation. Plants need to be scanned with an infrared camera annually – while the legal requirement is to scan 20% of the plant, that’s not optimal; the 20% you scan may not be uniformly representative of the whole plant. The heat creates additional challenges: as the ground may be close to the same temperature as hotspots, this needs to be taken into consideration.

“Thermography is both art and science,” says Meyer, pointing out that images need to be taken from the correct angle in order to be accurate. Prior to the use of drones, the images were taken with a handheld thermal camera: depending upon the terrain, achieving the perfect images on foot could be nearly impossible. Drones take care of the problem, able to provide the accurate imagery over the entire plant in less time than it might take for a handheld inspection of 20%.

Accurate drone data is not only able to identify hot-spots on the panels, but slight temperatur variations that couldn indicate a panel is inactive. This can happen for a variety of reasons including weather event and equipment damage, but non-functioning areas of the plan can be extremely costly. With a numerous examples at hand, Meyer refers to one case study where disconnected strings, previously undetected, resulted in a loss to the company of 750000 rand.

While the value of drone technology is undisputed, it can be hard to explain to staff unfamiliar with the potential. But as Meyer and his team continue to utilize drones on renewable energy plants across the continent, the benefits are becoming clear to an entire industry.

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, a professional drone services marketplace, and a fascinated observer of the emerging drone industry and the regulatory environment for drones. Miriam has penned over 3,000 articles focused on the commercial drone space and is an international speaker and recognized figure in the industry. Miriam has a degree from the University of Chicago and over 20 years of experience in high tech sales and marketing for new technologies.

For drone industry consulting or writing, Email Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife here.

[…] नियरथलैब, एआई-सक्षम प्रदान करता है पवन टर्बाइनों के लिए ड्रोन निरीक्षण: पारंपरिक तरीकों की तुलना में समय, धन […]