The following is a guest post by Dor Abuhasira, CEO of Percepto.

Running an infrastructure operation is expensive – and maintenance is one of the biggest expenses of all. Maintenance isn’t just about major repairs to machinery, or ensuring that waste removal systems work properly; it’s also about the million and one little things that could go wrong, and could halt operations if they do.

For operators of large industrial or infrastructure facilities – factories, warehouses, oil refineries, electricity generation plants, etc. – the little things can indeed be critical, especially from a financial point of view. A hole in a fence, a broken pipe, a blown socket, corrosion, cracks in the chimney – all these things could spell big trouble for an organization, and end up costing it a pretty penny. Small problems can crop up at any time – but often aren’t noticeable until they turn into big problems, especially if they are on a roof or in a remote area of an outdoor facility that is difficult to get to or entails risks for staff to observe.

Outages and shutdowns at large industrial or infrastructure facilities can wreak havoc on an organization’s ability to deliver services, destroy their reputations, and expose them to lawsuits. Especially problematic are infrastructure that is not within the purview of maintenance teams inside a facility – such as an outdoor transformer on the grounds of a cogeneration plant. While the maintenance teams may be keeping a close eye on the equipment indoors, they may not be giving outdoor equipment, infrastructure, or other key items the same attention – thus leaving the organization vulnerable.

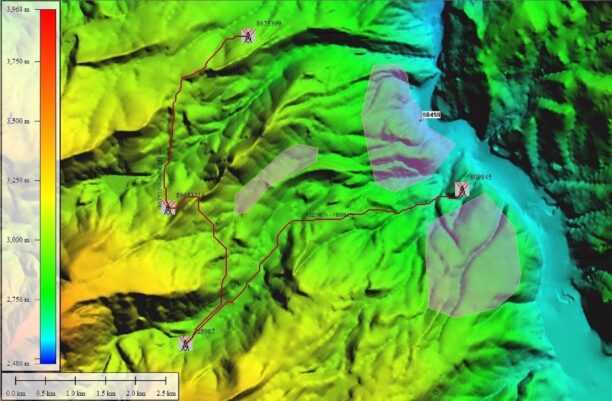

One way to avoid these situations is by deploying autonomous drones. Flying on their own on a preplanned route, without the need for an operator, fleets of drones can produce aerial images of hard to see locations, and can observe everything going on in a large outdoor facility. These drones can be equipped with machine vision, artificial intelligence, and other advanced technology to ensure that they are able to detect the extent of a problem – whether it is large enough or serious enough to warrant the attention of staff – and alert the right people when necessary, enabling them to take action when the problem is still small and inexpensive to fix. At an infrastructure plant, for example, drones equipped with infrared or thermal cameras and sensors can detect leaks, fence breaches, excessive pollution, etc. The system can be robust enough to detect the abnormalities and eliminate false alarms, pinpointing the exact location of the problem – thus saving the maintenance team the need to pore through hours of video in order to determine if there is a problem.

There are, of course, alternative ways of finding these things out – like when a leak turns into a flood, or an intruder makes it through a hole in a fence to the facility itself, or regulators take note of the emissions at a site and slap it with a huge fine. Facilities could also send out ground teams to inspect all potential problems, but that would require having patrols out on site, which can prove extremely costly and is often impractical for many companies. It’s the flexibility of autonomous drones that make them essential to managing and maintaining large outdoor facilities.

Autonomous drones help save money in other ways, as well – 80% of security “breaches” are false alarms, often due to human error, but regulations require that all alarms be checked out – otherwise the facility could be held liable if a legitimate security incident halts operations. A drone operating autonomously that regularly flies over the perimeter of a facility can respond to an alarm as soon as it is sounded, differentiating between false alarms and the “real thing,” thus saving time and money by obviating the need to send out inspection teams.

Besides safety, security, and maintenance issues, autonomous drones can also ensure compliance with regulations. Many infrastructure facilities are today considered critical infrastructure, which governments require to have more effective security controls than ever. Same goes for environmental standards and requirements – autonomous drones with specialized equipment, such as thermal cameras, can ensure compliance and avoid fines, etc.

While the idea of autonomous drones flying around and providing all these services sounds futuristic, the truth is that the technology to do all this exists right now, and even out of the box, commodity-produced drones can be equipped with the resources to make them autonomous. Regulations, which have prevented widespread use of autonomous drones, are slowly but surely catching up – and about time, too.

Dor Abuhasira is the CEO and Co-Founder of Percepto, an Israeli company developing fully autonomous drone systems. Prior to co-founding Percepto, Dor served as a key member of the engineering team at NetOptics, a network visibility company acquired by IXIA in 2013. Dor led GPON technology at ECI Telelcom from 2010 to 2013.

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, a professional drone services marketplace, and a fascinated observer of the emerging drone industry and the regulatory environment for drones. Miriam has penned over 3,000 articles focused on the commercial drone space and is an international speaker and recognized figure in the industry. Miriam has a degree from the University of Chicago and over 20 years of experience in high tech sales and marketing for new technologies.

For drone industry consulting or writing, Email Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife here.

[…] Source link […]