European-based Airobot and renewable energy experts Mind4Energy have joined forces to develop a “flying robot” for detailed solar farm inspections. The project is supported by an innovation grant from the Province of Limburg, Belgium.

European-based Airobot and renewable energy experts Mind4Energy have joined forces to develop a “flying robot” for detailed solar farm inspections. The project is supported by an innovation grant from the Province of Limburg, Belgium.

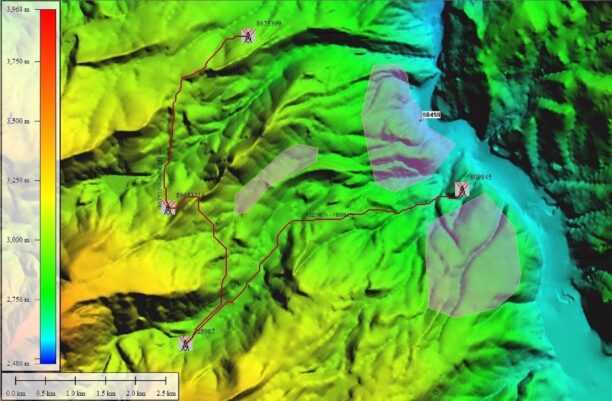

Solar plant inspections are a high value application for drone technology. With European plants getting larger all the time, says Airobot, detailed inspections are key to a plant’s success. “To guarantee the energy output, malfunctioning panels need to be detected and replaced as quickly as possible,” says the company. “Today, infrared cameras on drones enable easy detection of defect panels, but the technology isn’t accurate enough to predict where problems will pop up. Ideally, each panel should be inspected frequently for damage or soiling. And in these large solar farms it takes a person at least one day to walk the complete site.”

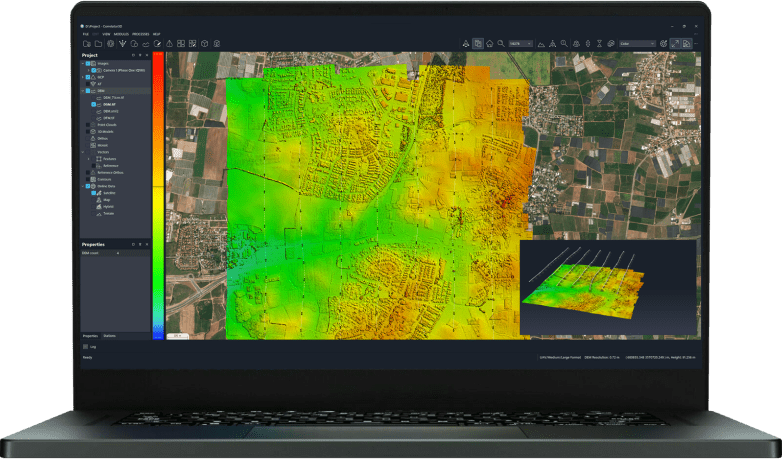

Airobot provides technology for commercial and enterprise drone applications. Collision-avoidance, navigation and positioning systems allow commercial drones to significantly improve the quality of data collection by ensuring consistent flight – and meeting enterprise safety requirements. Airobot’s data solutions send data to the cloud for client access. Mind4Energy specializes in engineering, monitoring and maintaining renewable energy installations. Their complete solution includes engineering, installation of hardware, monitoring and data delivery. The two companies’ combined expertise make them a perfect team for development of the solar panel solution.

“In this project we’re going to turn a professional drone into a flying robot for solar panel inspections”, says Jan Leyssens, Managing Director at Airobot, “we’ll add technology to make the drone fly safely and automatically at low altitudes above the panels and record with centimeter accuracy where the pictures are taken. The images will be stored in the cloud and processed with Artificial Intelligence to detect panels with problems”. The goal is to reduce the operational costs of solar park owners by doing better preventive maintenance.

“This project will bring us a new tool to offer a better service to our customers”, adds Dirk Eeraerts, Co-founder at Mind4Energy, “it will help to get us a fast overview of the panels that need maintenance or cleaning which allows us to increase the lifespan of the installation and, in the end, reduce the cost of energy”.

The project will run throughout 2018 and first results are expected by the end of the year.

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, a professional drone services marketplace, and a fascinated observer of the emerging drone industry and the regulatory environment for drones. Miriam has penned over 3,000 articles focused on the commercial drone space and is an international speaker and recognized figure in the industry. Miriam has a degree from the University of Chicago and over 20 years of experience in high tech sales and marketing for new technologies.

For drone industry consulting or writing, Email Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife here.

[…] Drones are already an established part of the maintenance process in the energy sector, from Sky Futures’ oil and gas inspections to Airobot’s use of UAVs on solar farms. […]