Kespry, the aerial intelligence platform provider, today announced that it has enhanced the Kespry Drone 2 with higher performance features that deliver significantly greater accuracy and reliability.

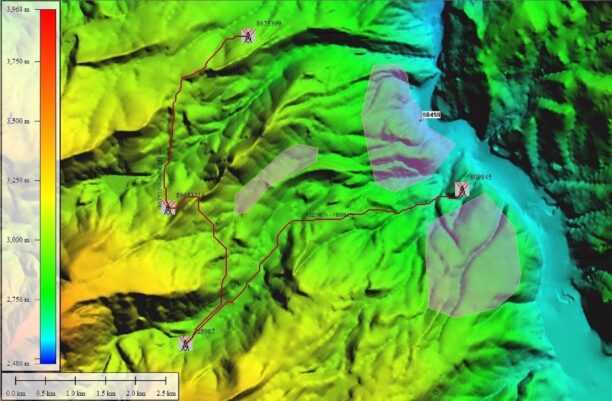

These enhancements enable the Kespry Drone 2 to better address a wide range of industrial applications, including those requiring survey-grade precision, including mining, architecture, engineering and construction (A/E/C) markets. The new Drone 2 now achieves four to six times the accuracy of the previous Kespry Drone System.

“Customers are looking for a complete drone solution that provides survey grade accuracy, without sacrificing speed and convenience,” said George Mathew, CEO and chairman of Kespry. “ The enhancements to the Kespry Drone 2 – bringing centimeter-level accuracy – exemplify how Kespry is innovating the industrial drone space through its Aerial Intelligence Platform.”

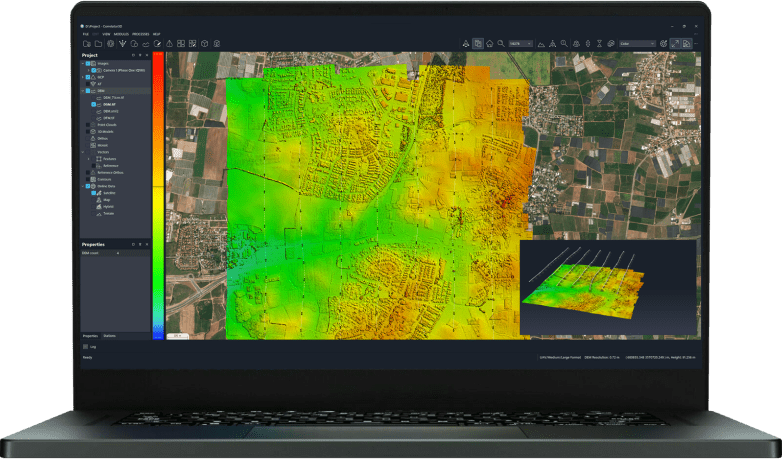

By adding a high-performance ground receiver, the Kespry Drone 2s can deliver accuracy of two to 10 centimetres. The Global Navigation Satellite System (GNSS) base station receiver serves as a single survey control point. During a flight, imagery from the Drone 2s and data from the base station are collected simultaneously. Both data sets are automatically uploaded for processing in the Kespry Cloud where accurate survey-grade data is automatically generated.

Such degrees of accuracy are critical for mine planning, determining boundary lines, positioning underground utility cables and pipes, and other survey-grade applications. The single ground control point simplifies survey applications as it eliminates the need for multiple control points and additional manual measurements in the survey process.

“When we started working with the Kespry Drone System about a year ago, we were trying to find ways to be more efficient,” said Murry Cline, vice president of operations with APAC-Central, Inc. “We can now fly our Kespry Drone 2 over our entire 60-acre aggregate site in about 15 minutes. Previously, it would have taken us about a day or a day-and-a-half to do the inventories and a few more days to do the calculations.”

Post-Processed Kinematic (PPK) technology is used to increase the accuracy of photogrammetric aerial images. Integrating PPK improves the speed, efficiency and reliability of gathering survey-ready data in commercial and industrial environments.

“We’re ready to take the Kespry system to the next level, go beyond calculating inventories using the drones for things like mine planning and other applications that will give us an even greater business advantage,” Cline said.

The enhanced Kespry Drone 2 and Drone 2s are available now and are already being used by a range of customers like APAC-Central, a subsidiary of Oldcastle Materials, Inc., an industry leader in asphalt and concrete pavement construction, materials and services.

Frank Schroth is editor in chief of DroneLife, the authoritative source for news and analysis on the drone industry: it’s people, products, trends, and events.

Email Frank

TWITTER:@fschroth

[…] Source: dronelife […]