Hensel Phelps have completed over $1 billion in hospitality projects in the Washingto DC metro area. They’re a top firm in their field: and with recent FAA approval for flight over humans, Hensel Phelps is helping to push the boundaries of drones in construction.

At InterDrone this week, Richard Lopez of Hensel Phelps and Avi Lozowick of drone safety systems firm ParaZero provided an insider look at what it took to receive the waiver – and how it’s moving both the construction and the drone industries forward.

A Culture of Safety

Almost every firm claims a culture of safety – but at Hensel Phelps, it’s top of mind. The company’s website lists a “Zero Accident Safety Culture” as one of the top priorities of their building philosophy. Lopez says that the concept of safety is such an emphasis for the firm that it shapes the way that they approach any new technology.

“People may not realize that liability is a big part of our understanding of the use of the tool going forward,” says Lopez. “When we go to a job site, we have our employees stretch before working so that they do not pull a muscle,” he explains. “It is that type of philosophy that we bring to drones.”

Over time, Hensel Phelps has evolved their drone program from trying to do it themselves, to outsourcing, and back around to bringing a structured and carefully managed operations in-house and getting one of the first waivers to fly over people on a construction site. Hensel Phelps started with drones before commercial regulations even existed. “In 2013 we purchased our first drone at Sharper Image – and crashed in the first day,” says Lopez. “But it was the first step, and we know a lot more than we did then.”

The program moved to outsourcing drone services, but with a price tag of about $25,000 per location, it was clear that an in-house program would optimize the return. “We understood that drones were a great tool, but that we needed to understand how to fly drones legally and safely,” says Lopez.

Operational Procedures and Drones for Safety

Lopez says that Hensel Phelps quickly realized that operational procedures had to be carefully evaluated and updated to accommodate drones on the job site. “We had a drone early on hit a crane: but because we did not have policy at the time, no one knew that that should be reported,” he says. “That is something that we added.”

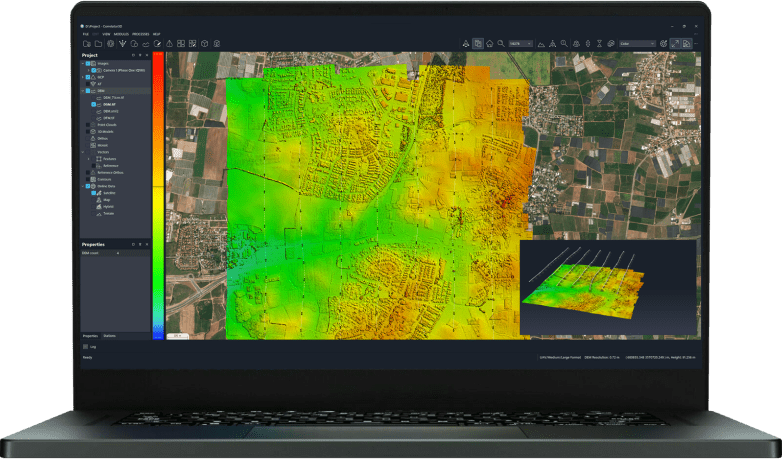

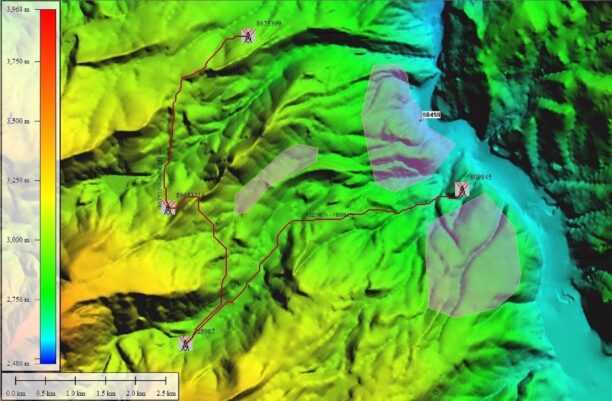

After deciding to bring the program in-house, Lopez’ team went from district to district and trained pilots. Now, they use drones to monitor job sites (Hensel Phelps primarily uses drone footage with digital simulations to show what the building will look like prior to construction. )”…All of our drone footage is reviewed by a safety manager before it is released to marketing.”

“Much of the time we have crews coming from outside of the state who may work for different companies that may not do all of the things that we do for safety,” says Lopez. “The drone allow us to identify and correct that type of behavior before we get hundreds of feet up in the air.”

Hensel Phelps follows stringent procedures like checklists, flight tracking, authorization procedures, and risk assessments. But with most missions taking place on a crowded jobsite, the company has established some safety rules and procedures specific to their application. “We stay 500 feet or more away from buildings,” Lopez explains. “Any closer is is a distraction to the crews… We also create drone zone map for all of our worksites, and discuss in advance things like emergency landing sites per zone.”

The Waiver for Flight Over People

Avi Lozowick of ParaZero says that the Hensel Phelps safety focus made them the ideal partner for applying for a waiver for flight over people. ParaZero provides the SafeAir drone safety system that was critical to the waiver approval. “Hensel Phelps was one the first waivers approved for flight over people in construction – that was done in June of this year,” says Lozowick.

“We needed a partner to go to the FAA for this waiver,” Lozowick explains. “Hensel Phelps had the culture and the processes to be a perfect partner.”

Hensel Phelps had the perfect drone operations program to support the application – and ParaZero had the data and statistics. As the industry has expanded, says Lozowick, it has become easier to prove the safety case for flight over people. “The FAA is looking for data,” he explains, “and up to a few years ago we had limited data.” ParaZero has invested heavily in working closely with regulatory agencies to provide them with the data they need. The company had a leading role in establishing the ASTM standards for drone parachutes. ParaZero’s team did more than 45 test flights where they deployed their parachute with 100% success. Those 45 test flights resulted in 45 pages of data: “Each test had a one page report that we use as part of our waiver process,” says Lozowick.

Producing all of that data has paid off for the company. “Hensel Phelps was the first one, now we have 17 waivers: including CNN and Fox,” says Lozowick. “Today, we provide documents that help both large and small companies get through the waiver process.”

Richard E. Lopez is the National UAS Operations Executive with Hensel Phelps Construction Co., an employee-owned company that over the last 81 years has grown to be one of the nation’s most recognized general contractors, serving both public and private clients. Richard leads the implementation of new Drone technology, software, and advancements at Hensel Phelps to increase efficiency and safety on the jobsite while providing valuable information for forecasting, recordkeeping, and as part of the procurement and construction efforts.

Richard E. Lopez is the National UAS Operations Executive with Hensel Phelps Construction Co., an employee-owned company that over the last 81 years has grown to be one of the nation’s most recognized general contractors, serving both public and private clients. Richard leads the implementation of new Drone technology, software, and advancements at Hensel Phelps to increase efficiency and safety on the jobsite while providing valuable information for forecasting, recordkeeping, and as part of the procurement and construction efforts.

Avi Lozowick is Vice President of Policy and Strategy at ParaZero Drone Safety Systems where he helps companies expand their operational flight envelope with waivers and approvals. Before ParaZero, Avi led the business development team at enterprise software startup, prooV. Avi initially joined the startup world via the Israeli venture capital firm OurCrowd, where he was an Analyst on the investment team. Avi holds a BA in Economics and Business Administration from The Hebrew University. He served in the Israel Defense Force for 3 years as a Tank Commander in the armored corps.

Avi Lozowick is Vice President of Policy and Strategy at ParaZero Drone Safety Systems where he helps companies expand their operational flight envelope with waivers and approvals. Before ParaZero, Avi led the business development team at enterprise software startup, prooV. Avi initially joined the startup world via the Israeli venture capital firm OurCrowd, where he was an Analyst on the investment team. Avi holds a BA in Economics and Business Administration from The Hebrew University. He served in the Israel Defense Force for 3 years as a Tank Commander in the armored corps.

CEO DroneLife.com, DroneRacingLife.com, and CMO of Jobfordrones.com. Principle at Spalding Barker Strategies. Has enjoyed working with and around the commercial drone industry for the last 10 years. Attendance and speaker at Industry Events such as Commercial UAV, InterGeo, Interdrone and others. Proud father of two. Enjoys karate, Sherlock Holmes, and interesting things. Subscribe to all things drone at DroneLife here. Email is Harry@dronelife.com. Make Sure that you WhiteList us in your email to make sure you get our Newsletter. Editor1@dronelife.com.

[…] technology can also be employed in the commercial construction industry, autonomously generating high-resolution models of construction projects, which could be imported […]