Paul Ross is meeting people he never thought he’d run across – who work in places he never thought he’d see. But as enterprise drone solution Kespry‘s VP of Marketing, he’s seen the adoption of commercial drones expand from a few core businesses like construction and insurance into totally new industries.

It’s a trend that makes sense, Ross says, given that industries are now realizing that drone data is a new way to solve an old problem: keeping business profitable.

“Our clients now are often accounting managers, or other core business managers,” says Ross. “Being vertically focused has allowed us to expand into sub-verticals. In the paper and pulp industry, for example, the challenges that the company faces is essentially the same challenge that is being solved in the mining and construction industry,” he explains. “They have a quantity of material that is rarely measured, because it is so expensive to do that: but if you are getting orders on a daily basis and updates to your supplies very rarely, those things don’t match.

If you don’t have an accurate view of the supply, companies lose money.”

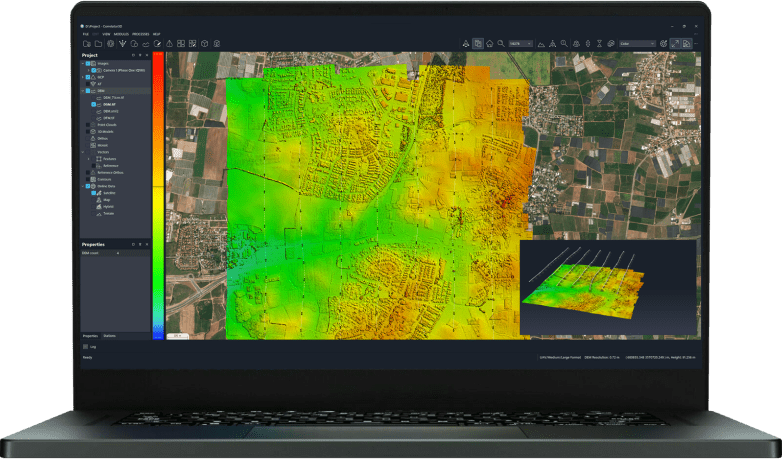

Kespry is focusing on making drone data as accessible and useful as possible, and meeting the needs of this new type of customer. “The next stage of drone data is ‘operationalizing,'” says Ross. “Our focus is on the larger companies now, and bigger companies are standardizing data sources. Standardization of data capture is a big theme, because the data is going to balance sheets, accountants, and auditors.”

The challenge for the drone industry, says Ross, is to educate enterprise companies about what problems drone data can solve. “The people that are missing from drone conferences are the people that are using the data –that’s where this needs to go next,” says Ross. “How are we going to get the people who are using this data to understand the drone industry?”

Kespry shared this interview with Ruth Keyes, the Environmental Coordinator at Mercer Celgar, with DRONELIFE. In this interview, Keyes explains how their company is using the Kespry system and drone data.

An interview with Ruth Keyes, Environmental Coordinator, Mercer Celgar

Mercer Celgar is a pulp mill located in Castlegar, BC, Canada. The Celgar mill is part of the Mercer International family and is recognized for efficiency and operational excellence, including EcoLogo certification for green energy production. Ruth Keyes is an Environmental Coordinator at Mercer Celgar, responsible for monitoring and reporting on the company’s activity and permits in three areas: landfills, effluent, and air quality.

When did you start to consider drone technology for Celgar?

Ruth: Mitch Dunlop in accounting identified that Kespry could be useful to survey the chip pile for inventory and knowing that other departments were also using external consultants for drone services, including the Environment department for landfill surveys it made sense to put those skills in the hands of mill employees.

Before you had Kespry, how did you go about completing landfill surveys?

Ruth: Before Kespry, we were hiring a service for quarterly landfill surveys, but the results that we would get were fairly limiting in terms of what we could actually do with them internally. We would get a PDF map, an aerial photo, contour data, and then a shape file, however we did not have GIS software to really use the data. The consultant would use the data to generate volumes or any other function we requested, but it can be time consuming and costly to be making small requests from a consultant.

How are you using Kespry to manage your landfill volume now?

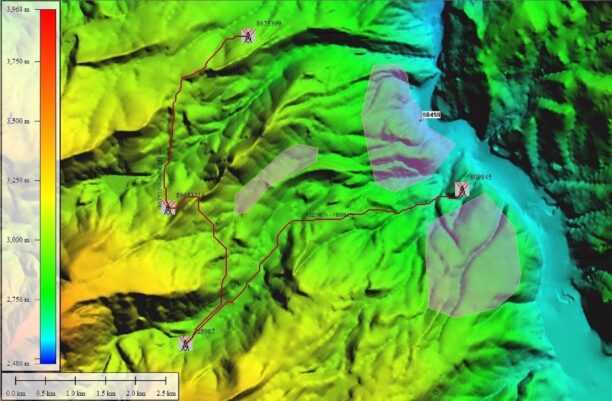

Ruth: We have a design from a consultant for our landfill capacity. We do drone surveys on demand to determine how much of the space we’ve filled , and how much remains to ensure we use the space effectively.

How often are you able to gather data using the drones?

Ruth: We have two landfills and I try to fly over each at least once a month. One of the landfills in particular I’ve been flying more frequently because there’s been so much activity. We are moving materials and temporarily stockpiling, so it’s been quite handy to keep track of the quantities for planning purposes.

Along with having more frequent data, how has drone technology improved the accuracy of your surveys?

Ruth: Using the drone is a helpful way to document how we track and manage our inventories and projects. Having the ability to survey at any given time allows us to see changes much more accurately and plan how to move forward based on results. Having multiple data points rather than only one survey every month or two gives a clear documented picture of landfill management.

Have you found other uses for drone surveys?

Ruth: After completing the training and starting to fly, we realized that there were a lot more applications to use the drone for than just the landfills and chip piles. One of the projects we’ve used it for has been looking at the high water level in the river to give consultants information for design criteria of our foreshore operations, ensuring we are in compliance with all regulatory criteria. We’ve also used it in waste management to estimate volumes and disposal options as well as discussed the potential use for flying inside confined spaces to conduct inspections of tanks or vessels.

How is Mercer Celgar using drone technology for other environmental protection?

Ruth: We can use the drone data to calculate remaining capacity in our spill ponds. These ponds are a critical component of our operation and are used during upset conditions to ensure the protection of the effluent treatment plant. Knowing of the available capacity based on volume calculations can assist in operational decisions and maintenance requirements of the ponds.

Do you expect to find more uses for your Kespry system in the future?

Ruth: I think Kespry would be really valuable for us in managing any sort of protected or difficult to access space. We have so many different areas in the mill, different things come up all the time that have to be surveyed for process improvements, capital projects, or a need for environmental monitoring during construction. I don’t actually think we’ve exhausted the number of purposes for it.

Do you have any advice for women wanting to explore your career?

Ruth: I think there are unlimited possibilities for women in this field. I don’t see any barriers at all. My background is actually civil and environmental engineering. I completed my schooling in Australia, and then I was able to really grow my career because I possessed the skills that were needed. My job is exciting because it’s really varied, and I think that’s a big appeal.

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, a professional drone services marketplace, and a fascinated observer of the emerging drone industry and the regulatory environment for drones. Miriam has penned over 3,000 articles focused on the commercial drone space and is an international speaker and recognized figure in the industry. Miriam has a degree from the University of Chicago and over 20 years of experience in high tech sales and marketing for new technologies.

For drone industry consulting or writing, Email Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife here.

[…] Source link […]