Inspection services are one of the most hyped and fastest growing verticals in commercial drones, with good reason. When it comes to return on investment, the drones have it – saving large energy and infrastructure companies millions over conventional methods. Now Intel and Cyberhawk have partnered on a major use case, one that demonstrates that return for the entire industry.

Inspection services are one of the most hyped and fastest growing verticals in commercial drones, with good reason. When it comes to return on investment, the drones have it – saving large energy and infrastructure companies millions over conventional methods. Now Intel and Cyberhawk have partnered on a major use case, one that demonstrates that return for the entire industry.

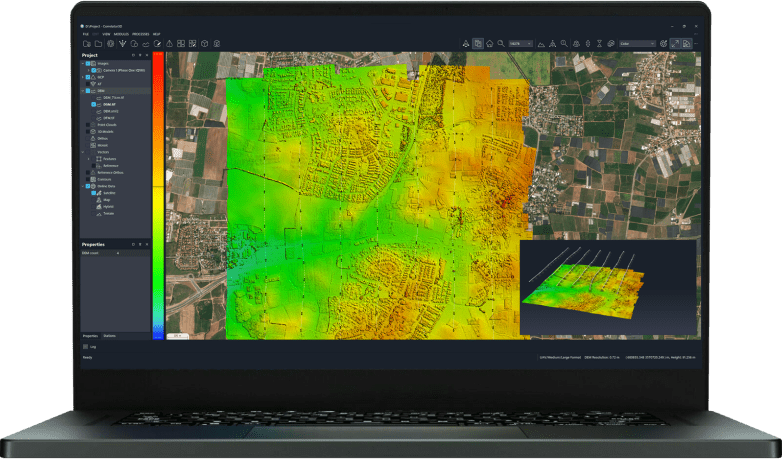

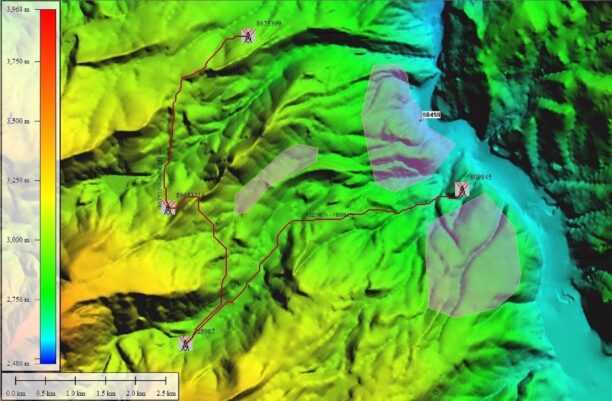

Intel introduced their Intel® Falcon™ 8+ system last year. It’s an aircraft built to meet enterprise (and regulatory) requirements for safety, engineered for stability and featuring numerous built-in redundancies. Cyberhawk, as global leader in aerial inspection and surveying and a respected figure in the industry, was a perfect choice of partner to demonstrate the drone in action and the value of drone technology to the industry.

Inspecting a gas terminal in St Fergus, Scotland, the companies say that they were able to save the client $1 -$5 million per day, while significantly reducing the risk to employees.

The return is so large because of the way these inspections are performed conventionally. Inspectors have to climb structures with harnesses and cable equipment – and one glance at the towers involved is sufficient to grasp the inherent danger in the job. In order for them to inspect the structure, it must be powered down. That’s a long and costly process: one that not only takes time but has a high cost in lost production for the plant.

The Intel Falcon 8+ captured over 1,000 images in 1 -2 days. A conventional inspection would have required a 3 man team to work for 3 days. “In the last 20 years that I’ve worked in the inspection industry, drones are the biggest single change we’ve seen to-date,” said Chris Fleming, Cyberhawk CEO.

“Unmanned aerial vehicle (UAV) technologies allow for large and complex facilities to be inspected while in operation, capturing accurate and precise data to better inform business decisions on asset maintenance,” says a company press release. “Drones are an important tool for the oil and gas industry, and the Intel Falcon 8+ system delivers reliable performance and best-in-class safety, especially critical when faced with challenging environments or dangerous situations.”

“Flying in Scotland, the devices have to withstand strong winds,” noted Fleming. “The Intel Falcon is perfect for that because it has the highest wind tolerance and the best power-to-weight ratio of any platform on the market.”

“The way we conduct inspections is changing,” said Anil Nanduri, vice president and general manager within Intel’s New Technology Group. “Drones make inspection workflows faster, cheaper and safer. The technology is mature enough to be adopted into the workflows of our customers.”

“This is not just about deploying drones,” says Nanduri. “This is about business tranformation.”

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, a professional drone services marketplace, and a fascinated observer of the emerging drone industry and the regulatory environment for drones. Miriam has penned over 3,000 articles focused on the commercial drone space and is an international speaker and recognized figure in the industry. Miriam has a degree from the University of Chicago and over 20 years of experience in high tech sales and marketing for new technologies.

For drone industry consulting or writing, Email Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife here.

[…] Inspection services are one of the most hyped and fastest growing verticals in commercial drones, with good reason. When it comes to return on investment, the drones have it – saving large energy and infrastructure companies millions over conventional methods. Now Intel and Cyberhawk have partnered on a major use case, one that demonstrates that […] The post Drones Save Over $1M per Day: Intel and Cyberhawk Partner on Gas Terminal Inspection appeared first on DRONELIFE. See Original Article […]