Staying alive as a small company in an emerging industry is always a challenge – so organizations that have made it for 10 years or more, growing along the way, are always worth looking at. Success isn’t always a straight path, and it takes flexibility and a determination to get things done to survive. NH-based ArgenTech (AgTS) is a perfect example of building a drone business by evolving to meet customer needs.

Staying alive as a small company in an emerging industry is always a challenge – so organizations that have made it for 10 years or more, growing along the way, are always worth looking at. Success isn’t always a straight path, and it takes flexibility and a determination to get things done to survive. NH-based ArgenTech (AgTS) is a perfect example of building a drone business by evolving to meet customer needs.

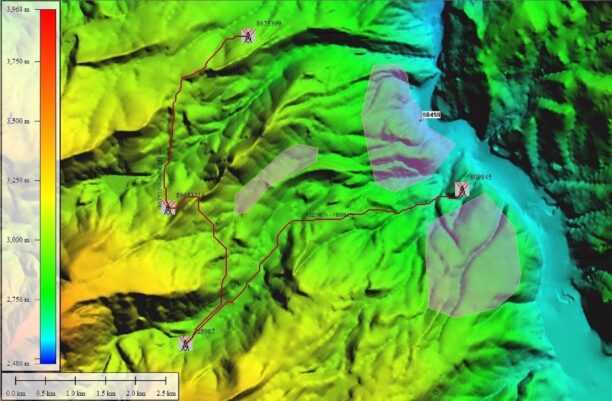

AgTS doesn’t have the word “drone” in their name, and that’s because they didn’t begin as a drone company. Started by a group of former military personnel in 2009, the company began with an SBIR grant for working with camouflage paint on submarines. In 2011, however, the company landed a contract with Insitu to work with the ScanEagle: flying, maintaining, and acting as site leads wherever the ScanEagle was deployed. The group had the military experience in manned and unmanned aviation required: but the ScanEagle contract was the start of a focus on drones for AgTS, to meet the market need for experienced operators of large UAS. A few years later, the company landed a contract in Colombia, mapping difficult terrain with drone-based LiDAR.

Bob Meyer, AgTS President of Flight Services, says the work was challenging – but it broke new ground for commercial applications. “We worked very closely with the Colombian CAA [Civil Aviation Authority] on the project. That gave us great experience. And working with LiDAR, we showed that we could map the terrain below the canopy. Nobody was working with [drone-based] LiDAR at that point.”

Building a Drone Business: from Service Provider to Drone Manufacturer

AgTS continued to build a team of manned aircraft and unmanned pilots, many from military backgrounds. (The company has won many awards for its policies of supporting and accomodating military personnel: it’s a practice that isn’t easy from an operational standpoint, but has led to a team with deep experience in the field.) They were growing in reputation and customer base as a service provider for large UAS, but a turning point for the company came 3 years ago when they were awarded a contract from the U.S. Department of the Interior Bureau of Land Management for fire survey work. The drone manufacturer that they intended to work with changed hands – and wasn’t able to deliver. That’s when AgTS decided to build their own large UAS for the work: the AgTS FireEye.

Rita Castonguay-Hunt, AgTS Program Manager, says it was a natural decision for the company. “A lot of what we’ve done over the last few years has been based on need,” she says. “We had a supplier lined up but when it came down to it, they weren’t able to deliver – so we had to make it happen.”

With an imported airframe and a Pixhawk open-source operating system, the FireEye is purpose-built for fire survey work. AgTS’ Jeremy Jones says that the company quickly established a manufacturing system designed for safety and standardization. “The manufacture of the aircraft itself is a full, controlled, process – we have full process control methodologies in place,” says Jones. “Standardization is our number 1 goal – the aviation industry succeeds on standardization, there’s no reason that the UAS industry can’t do the same.”

Once the aircraft was developed, the company knew they needed to develop training tools to meet their own standards. They’ve built their own training aircraft – and developed their own simulation program. It’s exactly the kind of training you’d expect from a company of manned aviators and military personnel. “We developed our training program out of need, too,” says Castonguay-Hunt. “Our program mimics the training we received as chief pilots – the manned aviation model which we know is safe. We just applied it to Argen Tech.”

Serving the Customer

With the AgTS aircraft, the team of trained service providers is ready to respond 365 days a year. “We’re staged on the West Coast with two birds and a truck,” Castanguay-Hunt explains. “When we get the call, we’ll fly whoever is on the watch list in to meet the truck. Mostly, response teams want maps and GIS information. The DOI managers with us will ask us to map the fire line; use EO/IR to look for people in case of a missing firefighter; and map any hot spots outside of the fire line that could reignite.”

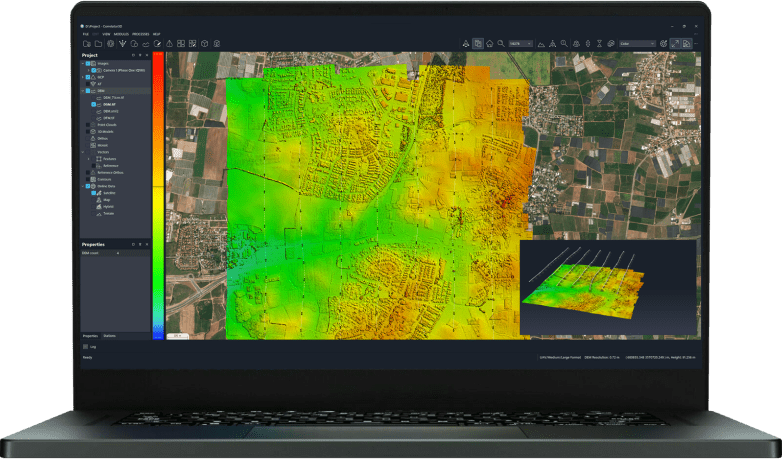

“We don’t fly in the stack where the tankers are flying in and out,” she says. “We’re usually flying at night, to stay out of manned aviation’s way.” In addition to the aircraft, the project requires sophisticated software and sensors. From the control truck, team members drop geotagged points on the sensor computer so that response teams have up-to-date and accurate mapping information.

AgTS is continuing to grow. “We’ve built an impressive aircraft that is only getting better,” says Castonguay-Hunt. “We’ve built a training program that I would stack up against any.”

“This year, we’re going to start expanding into other states and other markets – there are a lot of other places in the world that are experiencing wildfires that we could help,” she says. Whatever future customers’ needs are, AgTS is ready to fill them.

“We’re not a ‘one size fits all’ company: we’re a ‘let’s make this happen’ company,” says Castonguay-Hunt. “We have a level of expertise that is unmatched in the industry right now – and we’re ready to share that.”

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, a professional drone services marketplace, and a fascinated observer of the emerging drone industry and the regulatory environment for drones. Miriam has penned over 3,000 articles focused on the commercial drone space and is an international speaker and recognized figure in the industry. Miriam has a degree from the University of Chicago and over 20 years of experience in high tech sales and marketing for new technologies.

For drone industry consulting or writing, Email Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife here.

[…] Dronelife […]