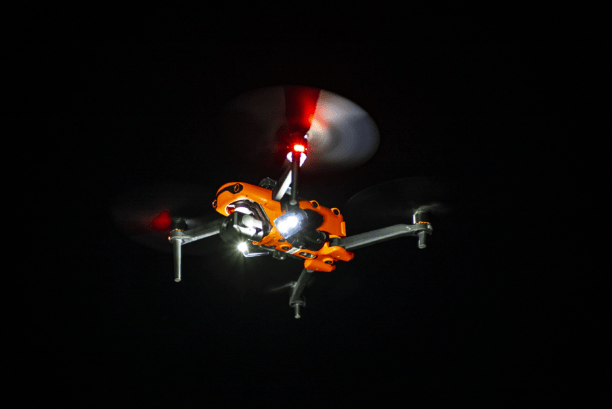

Autel‘s EVO II has been a compelling competitor to other commercial off the shelf (COTS) aircraft for the drone industry, and particularly in the public safety sector. The EVO II is well-equipped, easy to use, weather resistant, and relatively inexpensive. Partnerships like the one recently announced with drone mapping company Pix4D mean that public safety departments can purchase an integrated solution and get use out of it quickly. Now, the EVO II Dual Bundle can also be described as “A rapid-deployment, packable unmanned aircraft made in USA with foreign and US components and labor,” as today’s press release states.

The announcement represents a significant investment for Autel in its U.S. business, but not a shift in direction. While Autel Drones’s airframe manufacturing has been done in Shenzhen, China, arguably the global center of drone manufacturing; a significant amount of the work – and company management – has been based in the U.S. offices out of Bothell, WA. What has changed, amidst increasing pressure on Chinese technology companies, is the need for transparency about manufacturing and sourcing. By announcing that some Autel drones are manufactured in the U.S., the company is taking active steps to clarify exactly what parts are made overseas and what parts are made in the U.S.

“With an airframe from China, IR/thermal cameras from FLIR in the USA, and Sony imagers from Japan, the final product is assembled in Bothell, WA with American labor,” says the announcement.

“We notified our dealers that the change in manufacturing is effective immediately, and this new series of bundles does not impact our ability to ship existing stock. We have been making running changes to the product line in order to accommodate our customer needs since the day we initially released the product,” said CEO Gary DeLuca.

“We also source the majority of our bundle components from US manufacturers such as FoxFury, GPC, TacSwan, and others” said DeLuca. “Our software and other components are predominantly also from domestic and NATO suppliers. We’re deeply focused on shifting the product program to a Made in USA direction. We brought in outside consultants to assist us in identifying resources and processes that bring us closer to our American roots.”

Why “Made in America” is Important for the U.S. Drone Industry

“We are also proud to share that our solution does not require LTE for operations. Whether intelligent flight, or manual flight, our systems function without connecting to a server inside or outside CONUS,” added DeLuca.

“Autel aircraft may be flown without connecting a mobile device, as the remote control offers a 3.3” display for FPV,” the announcement explains. “When connected to a mobile device for preview and autonomous flight modes, the mobile device may be put into airplane/no-data mode once local maps have been downloaded for mission planning.”

“Autel prides itself on ensuring that user data remains private,” said John Kuch, who is also a former Fairfax County investigator. “Users are not required to sign up for an account, and are not required to input any data that they do not want shared. Data security combined with our domestic manufacturing efforts provide a safe, secure, and efficient environment for any public safety agency with our Autel EVO II™ Dual platform.”

Miriam McNabb is the Editor-in-Chief of DRONELIFE and CEO of JobForDrones, a professional drone services marketplace, and a fascinated observer of the emerging drone industry and the regulatory environment for drones. Miriam has penned over 3,000 articles focused on the commercial drone space and is an international speaker and recognized figure in the industry. Miriam has a degree from the University of Chicago and over 20 years of experience in high tech sales and marketing for new technologies.

For drone industry consulting or writing, Email Miriam.

TWITTER:@spaldingbarker

Subscribe to DroneLife here.