Aerial inspections are big business for a reason. As well as providing a host of industry sectors with cost savings and new levels of efficiency, they are also saving lives by replacing risky practices. Plenty of previously dangerous infrastructure inspections of bridges, buildings and cell towers are now being safely carried out with the help of a drone.

Here are seven separate examples of how drones are revolutionizing inspection services.

Bridges

Every day countless bridge inspections are carried out around the world. Some are more precarious than others, but nearly all carry with them some element of risk. Traditionally, a crew of engineers will use ropes or a mobile platform attached to a vehicle (or ‘snooper’) to perform inspections.

Depending on the location and size of the bridge, this can mean closing it down to traffic while inspections are carried out, and putting engineers at risk while getting on with their vital work. Instead, drones ensure that a team can stay on the ground as a drone (autonomously or carefully controlled) captures footage of the infrastructure areas concerned.

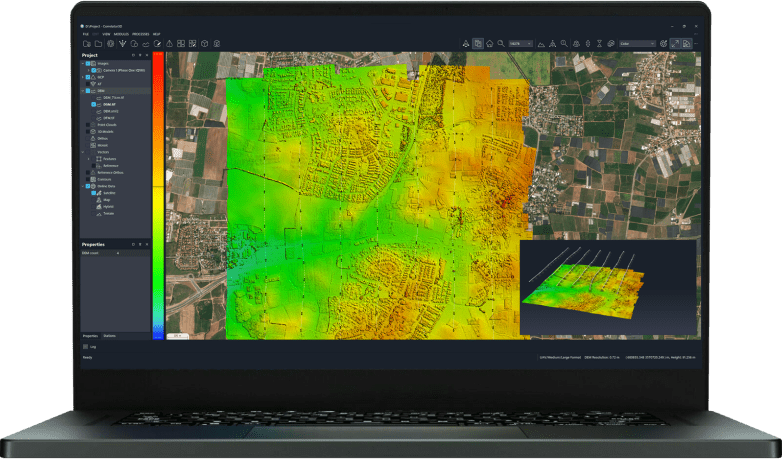

This footage can then be analysed (eventually by algorithms smart enough to detect structural defects) and used for presentation purposes.

Speaking to SenseFly, Jennifer Zink, the State Bridge Inspection Engineer with the Minnesota Department of Transport (MnDOT) Bridge Office, commented on MnDOT’s experience with drone technology so far:

“I don’t see any limitations at a drone level right now. It works well for what we need and the images correlate well with the inspection reports that we’re comparing them too. In the field we’re collecting various data, such as still images, video, infrared images, site maps and 3D models of bridge elements.”

“The results so far have shown that the inspection detail that UAS provide effectively replicates some of the detail learned through the use of snoopers, without the traffic control requirements, and at significantly lower cost in terms of equipment and traffic control needs. UAS can provide both infrared and 3D modeling detail of bridges, effectively identify concrete delamination, gather topographic mapping detail and efficiently map riverbank conditions, upstream and downstream, from the bridge site.”

Emissions

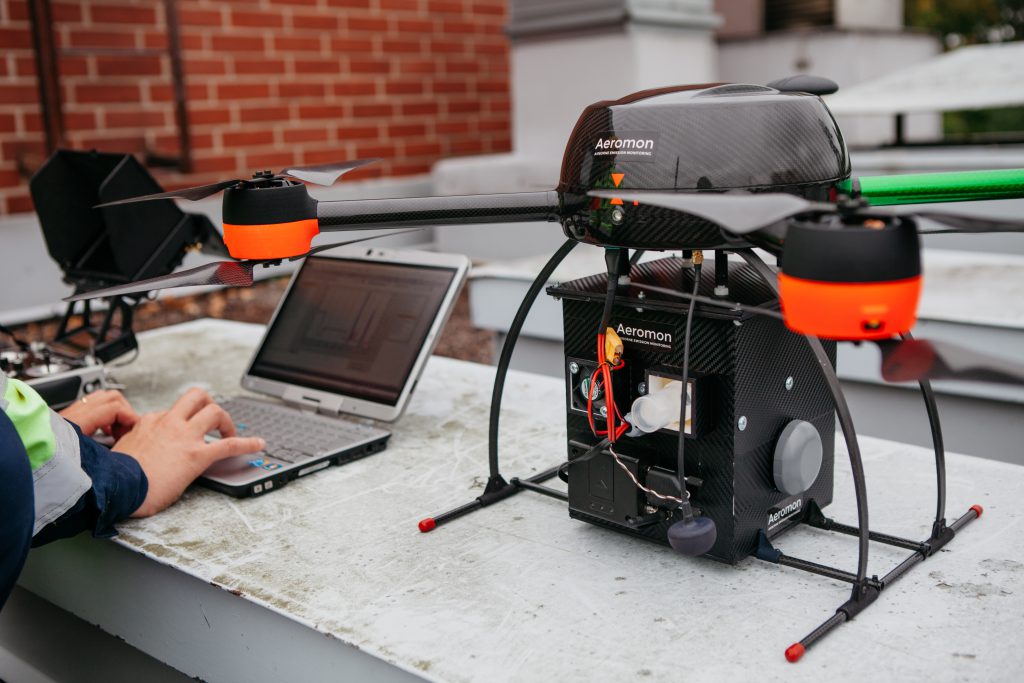

In our recent piece looking at how drones were being used for conservation purposes, we looked at Finnish startup Aeromon. The team has developed airborne sensors that can fly above industrial sites and inspect emission levels. Aeromon’s sophisticated sensor package, ‘BH-8’, is one-half of a drone and software platform capable of tracking toxic gases from above.

While it’s by no means a common use case for aerial technology, it’s easy to imagine this kind of inspection catching on in the near future. Especially at a time when many governments around the world are looking to reign in industrial emissions.

Aeromon chairman Jouko Salo definitely believes his company has found a niche in the growing drone market. “With emissions monitoring legislation tightening across the globe, the need for reliable fugitive emissions detection solutions is increasing,” he said.

Railroads

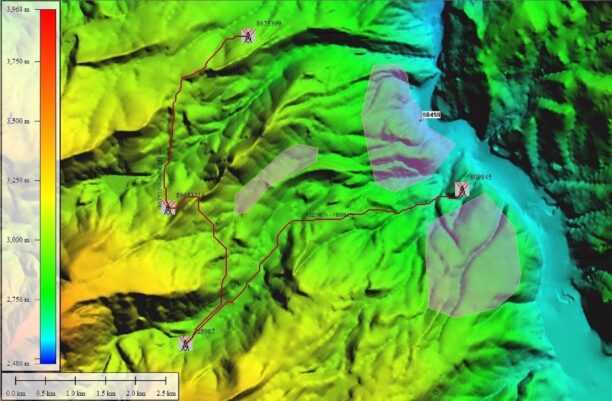

There’s a compelling case for railroad inspections from above. As well as having huge areas of land to cover, clever software can potentially detect damage more quickly and help prevent derailments as a result.

One company is way ahead of the rest when it comes to railroad inspection from above: BNSF. In fact, the company was named one of only three organizations to work with the FAA on its Pathfinder Program, developing a test case for operating beyond line-of-sight missions.

Back in October 2016, BNSF partnered with UAV developer Insitu to fly one of its ScanEagle fixed-wing aircraft along a series of railroads in New Mexico. The 135 miles of test flights remain among the first commercially operated missions to fly BVLOS in the US. “This has never been done before in the lower 48 states,” says Todd Graetz, unmanned aerial systems program manager, Telecommunications. “With this flight, we demonstrated that you can do this safely in scale.”

According to official BNSF documentation, BNSF hopes to receive the “FAA’s full blessing” for further operations by the summer of 2017, and is also “seeking to use multirotor aircraft flying in line-of-sight missions that would allow increased railroad overviews.”

“The more we fly, the more imagery we collect, the more we run it through the analytics, the better things get,” Graetz said.

Cell Towers

There are few better examples of the ways drones are revolutionizing inspections than when we look at cell towers. Let’s face it, nobody wants to be up one of these towers. And even in the cases where it’s necessary for a team of engineers to make the climb, they’d rather do so with the issue already diagnosed.

Drones are already helping to keep cell towers running efficiently, sending live video to monitors on the ground and giving technicians real-time control over flight paths to look for specific problems.

Art Pregler, director of national mobility systems at AT&T – one company leading te way with cell tower inspections – doesn’t expect drones to replace tower climbers altogether. However, he did say: “Every time we use a drone it’s just one less tower climb. Every tower climb that we can save provides a safer situation, or less opportunity for potential injury,” said Art Pregler, director of national mobility systems at AT&T.

“We’re seeing very accurate results from this data,” said Pregler. “We obtain it faster and we obtain it with more accuracy than we’ve been able to do with traditional methods. For example, instead of having to watch an entire video to understand what it is you’re looking at, we can tag all the various elements within there, so if we want to see, for example, a certain antenna or a certain radio, we can click on that tag and it takes us right to that spot.”

Apart from safety and efficiency, there’s another benefit to drone cell tower inspections that you might not be aware of. The evaluation of birds’ nests is currently one of the two most common uses for drones at AT&T tower sites. Because drones don’t touch the towers and come into contact with these nests, the disruption of protected species can be avoided.

“We’re not allowed to perform work on towers if there’s active nesting by an endangered bird, so we can fly the drone and inspect the nest without having to climb the tower, and know definitively if the bird is nesting,” Pregler said.

Oil & Gas

Drones are increasingly being used for onshore and offshore oil and gas projects around the world. Teams of pilots can operate on or around assets such as oil rigs to gather high-quality aerial data from above. In an industry where the concern for safety is paramount, often an aerial inspection can provide vital information and an emergency response service.

Many Oil and Gas operations will have to close down regularly for inspections, but getting as much information as possible via drone before that happens can make a huge difference. In fact, Sky-Futures CEO James Harrison below estimates that the data gathered from above in five days is equivalent to eight weeks’ worth of manual inspections:

Other benefits include the fact that there is virtually zero downtime needed during an aerial inspection, while lightweight UAVs offer little in the way of a health and safety risk.

Matt Harmsworth, CEO of Scottish drone operator ROAVR, has overseen worldwide UAV projects since the company was founded in 2013. He said: “The scope for use of SUAS offshore and onshore is great. But it must be carried out by correctly qualified and trained operators. We tend to look for pilots with a skill base rooted in the O&G industry and up-skill them to fly SUAS rather than try and send pure pilots offshore”.

“UAS allow us to de-risk planned operations,” he said. “They aren’t a golden bullet but form an important part of the overall inspection process.”

Solar Farms

Just as drones equipped with specialized sensors can fly over crops for a precision agriculture overview, the same technology can be used to inspect farms of a different kind. Solar farms are quickly seeing the benefits of drone technology, in both the planning stages and once operations are up and running.

A spokesperson from French UAV operator Dronotec told Dronelife that “Solar electricity production capacity is growing fast: The plants are larger, bigger and beyond the kind of scale that humans can handle.”

On top of offering cost savings, drones provide a safe way to inspect solar panels in what can be brutal locations.

“Traditional inspections conducted by humans in the field take a long time. On top of that, to properly inspect solar panels for defects, the best time to do it is when the sun is at its most powerful. This involves risks for the workers, especially when performing tasks in a remote area.”

The key to a solar farm inspection is the thermal imaging camera relaying footage back to an engineer on the ground. The data captured can help engineers discover broken panels or areas that aren’t running as efficiently as they could be.

Solar Inspections by Dronotec

“Using a drone you can map an area, detect invasive vegetation, spot dust on the solar panels and other problems that might occur (after strong wind for example). Thermal imaging can also detect defective panels that are overheating. This technology allows solar farms to “drastically reduce time on site and the exposure of workers to risks”.

Wind Farms

Another renewable energy industry is benefitting from drone technology: wind farms. Just as drones can help engineers spot defects in solar panels from above, they can also help to pinpoint damaged turbines and keep wind farms operating at 100%.

Cyberhawk, a company specializing in aerial surveys with drones, uses its technology to inspect wind farms in the UK and Europe. Cyberhawk has its own cloud-based asset management software called iHawk, which perhaps offers a glimpse at what many commercial operations can expect from drone data suppliers in the coming years.

As well as giving clients the ability to view the condition of their assets, iHawk provides high-definition visual evidence of the complete turbine blade and accurately sized, positioned and analysed defects.

Malek Murison is a freelance writer and editor with a passion for tech trends and innovation. He handles product reviews, major releases and keeps an eye on the enthusiast market for DroneLife.

Email Malek

Twitter:@malekmurison

Subscribe to DroneLife here.

A key trend in drone inspections that is indicated in the section on “Oil & Gas” will be that companies will look for pilots with a skill base in the industry and then train them to fly UAS rather than hiring pure pilots without industry knowledge.

Drone Pilots who plan to grab their UAS and go on inspections need to think about how industry experience will increase their chances of success.

One successful flight absolutely does NOT equate to ‘it can safely be done’. It will take hundreds of flights to prove safety. It took years to develop safe aircraft flight and we are still learning. So I warn those involved success doesn’t equate to safety it means you haven’t encountered the oh shit factor yet.