Cyberhawk Innovations is claiming to have completed another world first for the drone industry in the nuclear energy sector.

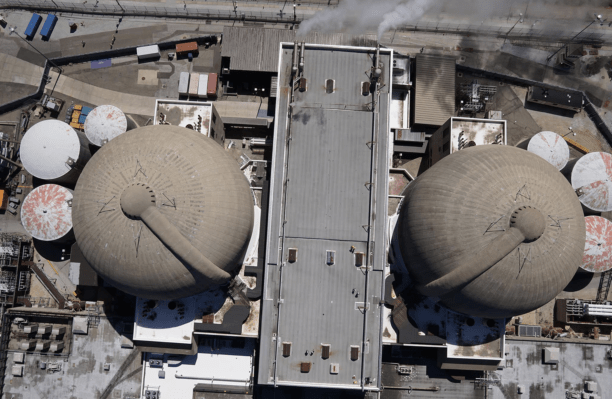

Cyberhawk has inspected two concrete PWR containment domes for American Electric Power at the Cook Nuclear Plant, located along Lake Michigan’s eastern shoreline. Although drones have been used in the nuclear industry, according to Cyberhawk, this was the first time a drone has been used by the American Society of Mechanical Engineers (ASME) according to the Section XI Code. The Code refers to several American Concrete Institute standards for completing an examination and this inspection has been recognised within the nuclear industry as a best practice based on these standards.

Inspections of this type typically involve using a man basket with a costly 60m (180ft) crane incurring that takes time to get the equipment on site and set up. It took one week for Cyberhawk to inspect both containment domes using a drone with minimal site disruption. The drone inspection generated direct cost savings of over 300% for AEP as well as significant indirect cost savings through reduced site disruption.

The drone inspection method involved capturing images of 100% of the dome surface to the ASME code standard, with the results digitised into a 3D point cloud that will allow direct digital comparison for any future inspections.

Cyberhawk was selected for this project because it is capable of conducting safe and efficient UAV inspections in hazardous areas. The team which mobilised to the site, including an experienced pilot and a highly qualified inspection engineer, completed the inspection to the ASME code examination requirements.

As a UAV company that has extensive experience within multiple projects and sectors, Cyberhawk’s pilots and engineers have a skillsets that enables them to successfully undertake projects of a challenging nature.

Chris Fleming, CEO at Cyberhawk, commented: “This was a challenging but very interesting project to be part of, and demonstrates how Cyberhawk continues to innovate, break barriers and challenge limitations. Once again, our pilots have shown an exceptional level of skill by successfully capturing the data required so our engineers could produce a detailed inspection report.

“It’s important to remember that whilst drones can collect a huge volume of data, a high-quality engineering report is what makes all the difference. This allows the client to easily assess the condition of the structure and plan any maintenance based on the data. For AEP, the final reports provided 100% visual coverage of the dome with exact sizing of defects and a 3D model of the structure. This was delivered using our cloud based visual asset management system, iHawk, which we continue to develop as our capabilities and client base grows.”

Frank Schroth is editor in chief of DroneLife, the authoritative source for news and analysis on the drone industry: it’s people, products, trends, and events.

Email Frank

TWITTER:@fschroth